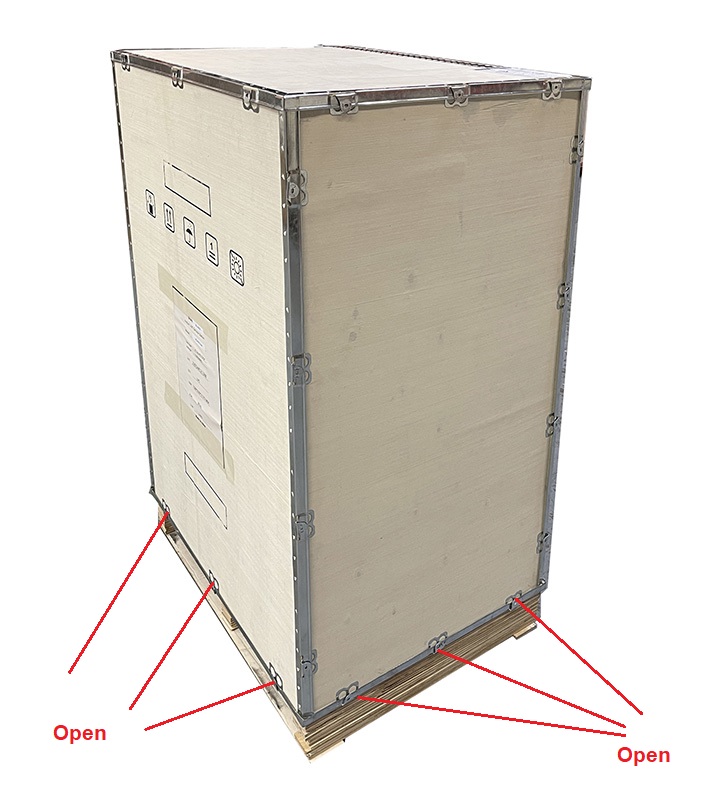

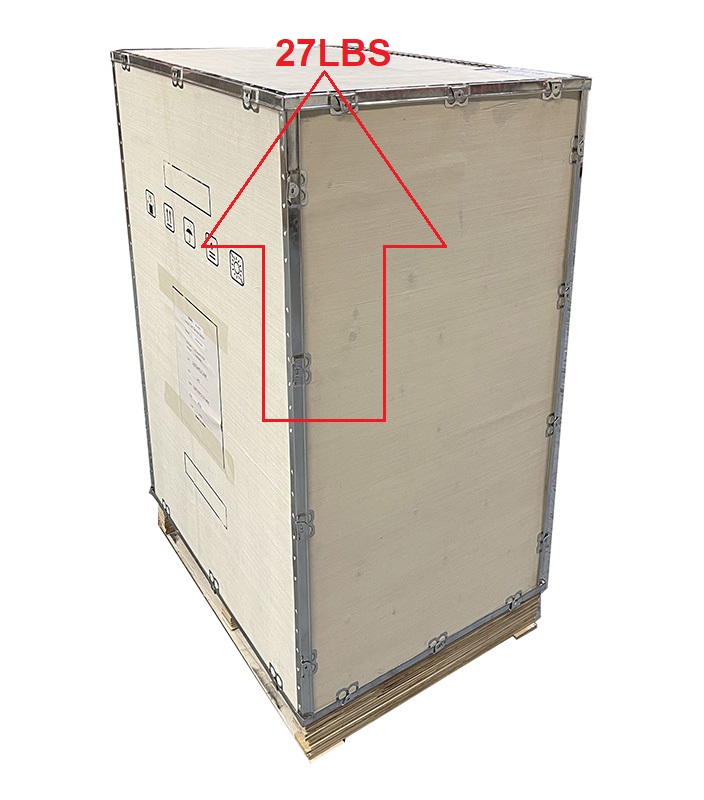

Unboxing:

- Unbox the shipping crate. You will need a flathead screwdriver, hammer, pliers, safety glasses and gloves. Using your tools, pry open the bottom row of metal tabs. Lift off the top portion of the crate. Weight is approximately 27lbs.

- Lift AC machine (approx 200lbs) out of the bottom of the crate carefully.

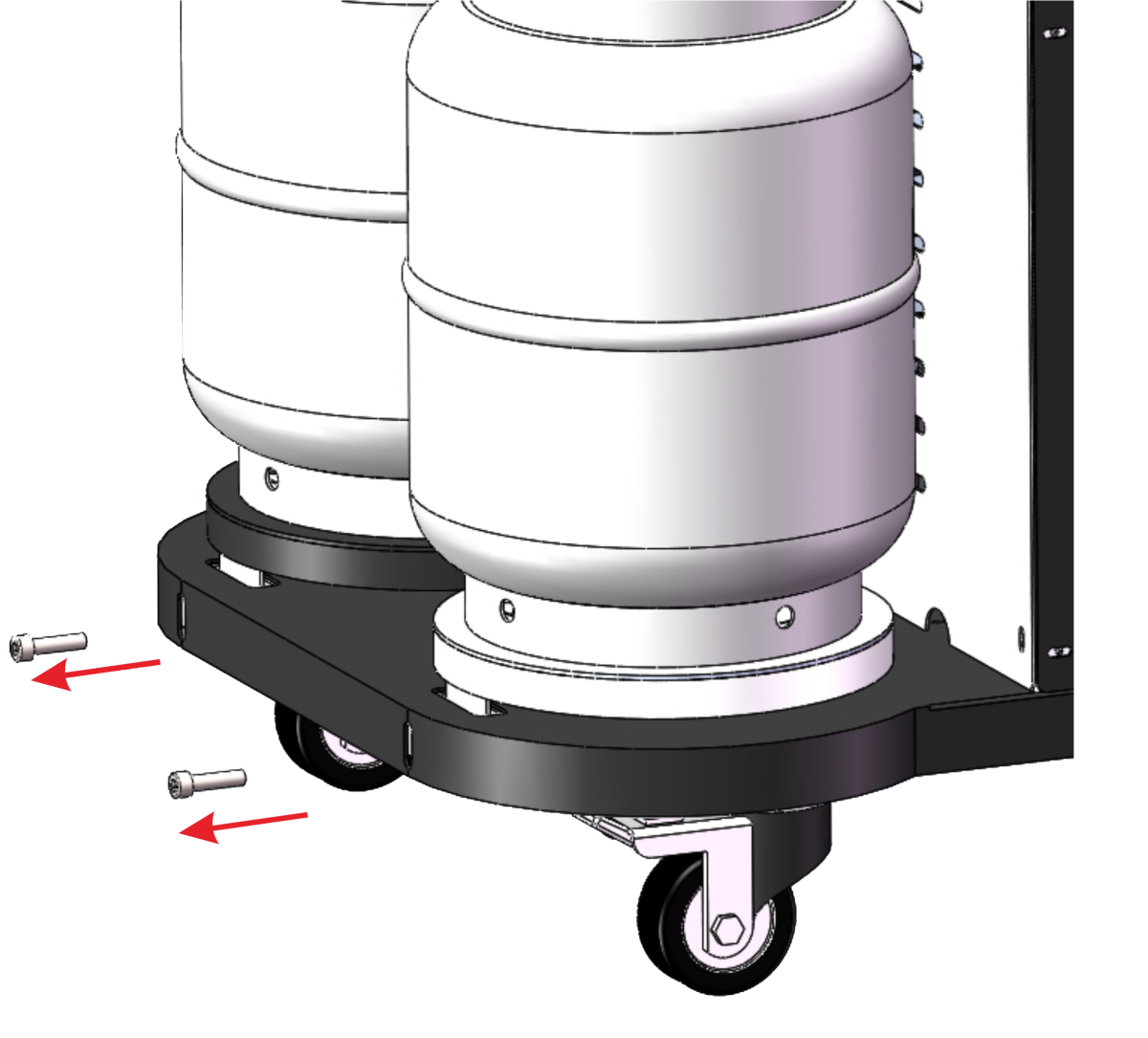

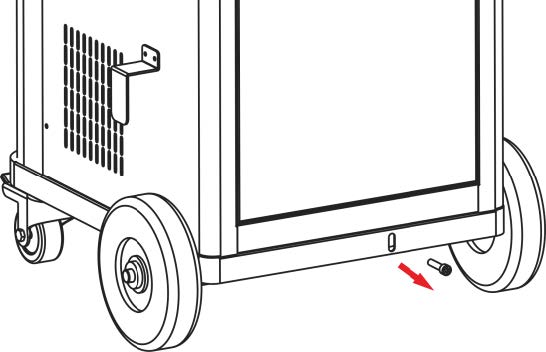

Machine setup:

1) Remove shipping bolt(s) on the backside of the machine, located underneath refrigerant tank(s). These bolts are only used to secure the scale during transit.

2) Make sure all fittings and hoses going into the machine are tight.

Machine calibration:

1) You must find 1KG or 2.2lbs weight to calibrate the scale(s). The weight must be 1KG or 2.2lbs exactly. The weight does not come with machine. Even you have a weight slightly more or less than 1KG weight and calibration shows successfully, but it makes all measurement inaccurately. If you can't find exact 1KG weight, skip the calibration procedure for later, DO NOT grab random weight to calibrate.

2) Turn on the machine. The power switch is on the upper right-hand side. Wait approx 30 seconds for the machine to boot up. (The screen will stay black during this time)

3) Use the arrow keys to select System Settings.

4) Enter password: 111111

5) Select calibration

6) Choose the refrigerant scale you are calibrating.

7) DO NOT put the weights on the scale until instructed to do so.

8) Place your weight on top of the corresponding refrigerant tank & valves.

9) Press enter key. You receive a message that the scale has been calibrated with a J

10) Use the settings menu to select unit of measurement and change it to lbs.

11) Exit settings menu

12) For AC400D machine calibration, you must do calibration on each mode separately. When you are in r134a mode, the calibration is only for r134a scale. If you want to do 1234yf tank calibration, then you must power off and on to switch into hfo1234yf and then do the calibration again.

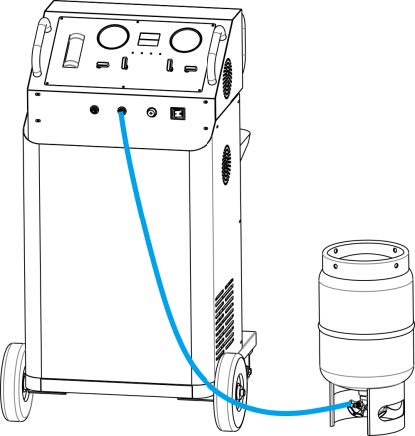

Tank filling

1) Before you fill the inside machine tank from source, check all the connectors and fittings are connected tightly, hand tight only

2) IMPORTANT: Never remove the internal tank for calibration, tank filling, recovering, vacuum etc... (when you remove the internal tank, the machine scale will never be able to calculate the amount of refrigeration in the internal tanks.)

3) Built-in tanks will be able to hold up to 20 lbs. maximum of refrigerant. However, you must leave some space for recovery. We recommend filling the up to 80% of the capacity, max 16lbs refrigerant. The machine requires a minimum of 4.4lbs to operate.

4) Connect the source tank to the low side (blue hose and connector). Make sure the high side coupler is closed. Do not leave the high side coupler attached to the machine or you will lose refrigerant. Make sure both valves are open on the corresponding tank inside the machine. Turn the source tank upside down.

5) On the display screen, select tank fill. Choose the amount of refrigerant to fill the tank inside the machine. Open the valve on the source tank. Select enter to begin filling the tank.

6) When the tank fill is completed, the machine will ask you to close the source tank valve. Wait until you see the LP gauge at zero. Once this is complete, you can remove the hose from the source tank. This will guarantee any refrigerant leak or release from the hoses.

7) Note: If you see a high-pressure message, then there is too much air inside the tank. You will need to complete an air purge to release the pressure. Use the air purge button to release air. Also, watch the gauge to get the pressure down to the proper level depending on the current temperature.

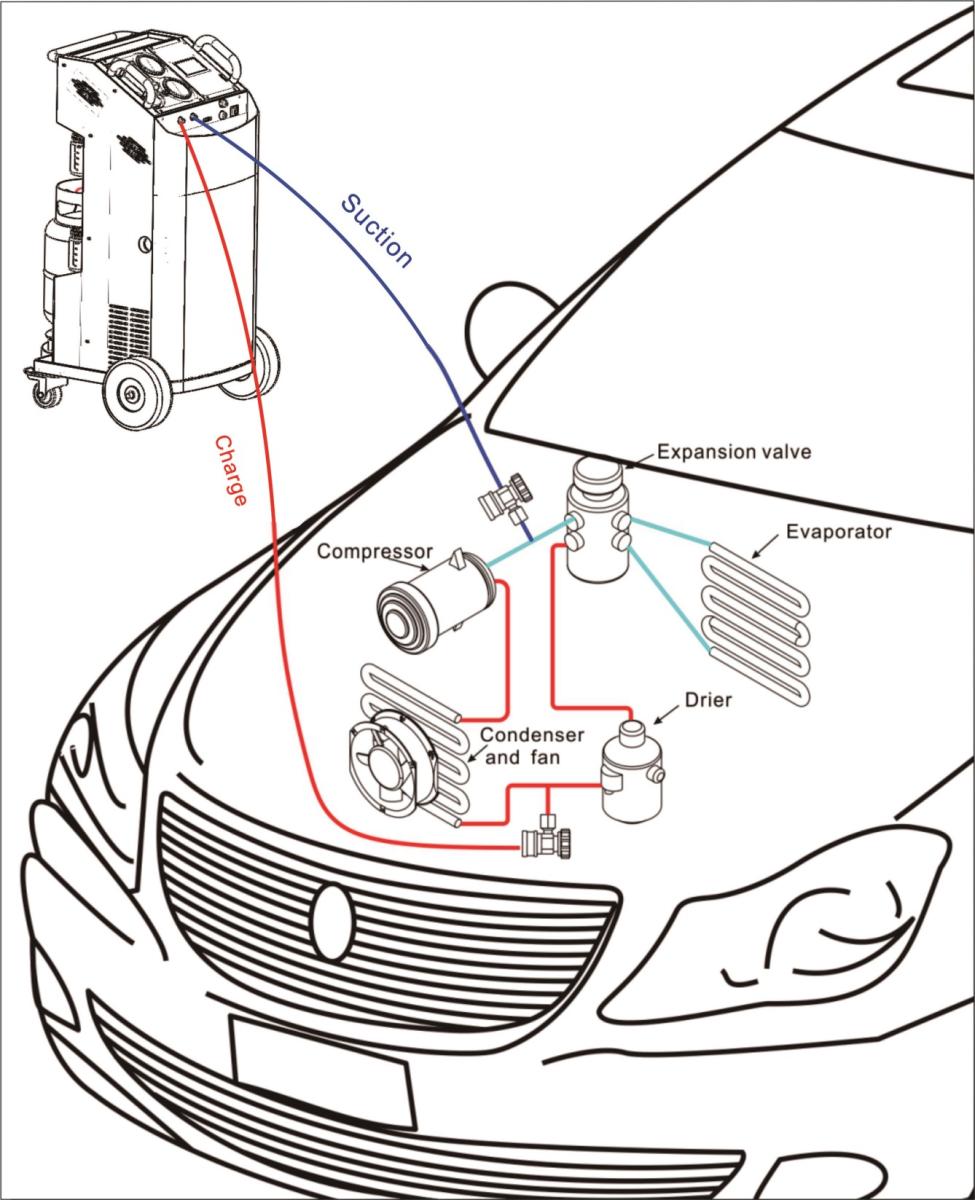

Recovery:

1) Turn off the vehicle prior to any AC service

2) Recovery will use both LP and HP at the same time. You must open corresponding internal tanks both the Red (HP) and Blue (LP) valves.

Vacuum and leak test

1) You can manually select the minutes to do the vacuum test. For best results, we recommend 8-15 minutes.

2) Leak test will hold vacuum for 3 minutes. The pressure on the gauges should read below 0. If the pressure increases, it means there is a leak in the system and the test will fail.

Oil injection:

1) When you vacuum the system, the used oil will be collected from the vehicle system and will go into the used oil bottle on the left-hand side of the machine.

2) Oil injections should be done during every recharge. If you replace a new compressor or condenser, check with the manufacturer’s recommendation for the amount oil injection.

3) HFO 1234yf does not allow injecting oil.

4) Hybrid or electric vehicles should be done manually, as they need POE oil, not PAG oil.

Recharge

You might select LP charge, high side charge, or both LP and HP at the same time to charge. We recommend to charge by HP (by default). If you are looking for vehicle refrigerant capacity, you are better looking at the vehicle sticker as a reference to manually type in the amount of refrigerant to charge.

Auto mode

Once the machine is set up, it will automatically complete recovery, vacuum, recharge, and oil injection procedures.

Settings:

Allows you to change units (lbs or kg), scale calibration, language settings, re-set cylinder weight and component test. The passcode is 111111 to enter the system setting on the menu.